Important Maintenance: Tips for Extending the Lifespan of Komatsu Undercarriage Parts

Wiki Article

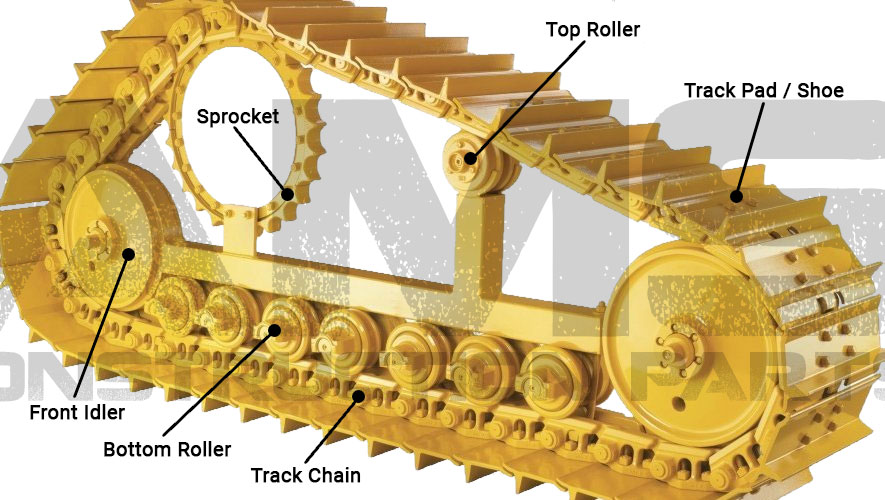

Secret Elements: Undercarriage Parts for Heavy Equipment

In the world of heavy equipment, the undercarriage works as an essential foundation that makes sure the smooth operation and durability of the devices. Secret components such as track shoes, rollers, idlers, gears, and track chains play a pivotal duty in the functionality and performance of these massive machines. Each element adds to the general security, traction, and longevity of the heavy machinery, making them vital for optimum operation. Recognizing the elaborate interaction of these undercarriage parts is crucial for upkeep and operational performance, prompting a better assessment of their value in the grand scheme of heavy tools functionality.Track Shoes

Track shoes play a critical role in the efficiency and toughness of heavy equipment's undercarriage system. These parts are vital for making certain traction, stability, and overall efficiency of the equipment. Track shoes are available in different layouts and products to fit various operating problems and surfaces. They are usually made from high-strength steel or various other resilient products to endure the heavy loads and harsh environments that hefty equipment operates in.

The style of track shoes is crafted to offer optimum ground get in touch with, reducing slippage and improving the equipment's ability to navigate difficult terrains (komatsu undercarriage parts). Correct maintenance and routine evaluation of track shoes are necessary to avoid early wear and guarantee the undercarriage system's longevity. Any type of indicators of wear, such as uneven wear patterns or too much damage, should be resolved quickly to stay clear of pricey repair services and downtime

Rollers

To enhance longevity and performance, rollers are normally built from top notch products like built steel, using resistance to tear and use under heavy lots and extreme working problems. Appropriate lubrication is crucial to reduce rubbing in between the rollers and track footwear, expanding the life expectancy of both parts. Normal examination and upkeep of rollers are vital to stop early wear and possible breakdowns, guaranteeing the continuous operation of heavy equipment.

Idlers

Idlers play a critical duty in the undercarriage system why not try these out of hefty machinery, functioning as important parts for maintaining correct track chain tension and guaranteeing optimal maker performance. Idlers are accountable for guiding the track chain and supporting the weight of the tools. These cylindrical rollers are purposefully placed along the track frame to distribute the device's weight equally, lower vibration, and enhance security during procedure.Appropriately operating idlers help stop premature endure the track chain and other undercarriage elements, eventually extending the life-span of the equipment. They also add to fuel efficiency by decreasing moving resistance and reducing the power required to move the equipment. Normal examination and upkeep of idlers are important to identify any kind of indicators of wear, misalignment, or damage that could cause efficiency issues or downtime.

Gears

Playing an essential role in the undercarriage system of heavy equipment, sprockets are essential elements accountable for moving power from the equipment to the track chain. Sprockets include toothed wheels or gears that harmonize with the web links additional info of the track chain, making it possible for the machinery to move forward or in reverse. These elements are normally made from high-strength materials like set steel to stand up to the extreme stress and friction produced throughout procedure. Sprockets come in numerous sizes and tooth configurations to match various maker requirements and applications. Correct maintenance and routine evaluation of sprockets are vital to make certain ideal performance and extend their life-span. Concerns such as damaged teeth or imbalance can lead to decreased performance and potential break downs. By understanding the importance of sprockets in the undercarriage system, drivers and upkeep workers can efficiently take care of these parts to boost the general performance and dependability of heavy machinery.

Track Chains

An essential part of the undercarriage system in heavy machinery, track chains play an essential role in sustaining and directing the activity of the devices. Track chains are robust steel chains that link the drive sprocket to the wheels or tracks of the heavy machinery (komatsu undercarriage parts). These chains are developed to sustain enormous stress, wear, and tension while making sure effective and smooth procedure of the machineryTrack chains are composed of individual web links that are attached by pins and bushings. The design of track chains is essential as it straight impacts the total performance and toughness of the heavy equipment. Proper upkeep of track chains is necessary to prevent premature wear, reduce downtime, and prolong the lifespan of the tools.

Routine assessments, lubrication, and adjustments are needed to keep track chains in optimal condition. read more Failure to preserve track chains can cause raised functional prices as a result of regular replacements and repair work. Investing in high-quality track chains and sticking to a stringent upkeep routine is essential to optimizing the effectiveness and longevity of hefty equipment.

Conclusion

In conclusion, the vital components for hefty equipment undercarriage components include track shoes, rollers, idlers, gears, and track chains. These components are necessary for the proper performance and procedure of heavy equipment, providing traction, stability, and support. komatsu undercarriage parts. It is critical for operators and upkeep employees to routinely inspect and keep these parts to guarantee the safety and security and performance of the machinerySecret components such as track footwear, rollers, idlers, gears, and track chains play a pivotal function in the functionality and efficiency of these huge devices. Service provider rollers help in sustaining the weight of the tools, while track rollers assist disperse the tons and make certain smooth track footwear articulation. Idlers act as a tensioning mechanism for the track chain, keeping correct track stress for optimal performance.

Track chains are robust metal chains that link the drive gear to the wheels or tracks of the heavy machinery.In verdict, the essential components for hefty equipment undercarriage parts include track shoes, rollers, idlers, gears, and track chains.

Report this wiki page